Why Nozzle Size Matters for 3D Printing and How to Choose The Right Size

As a 3D printing enthusiast with over 20 years of experience, I often get asked about the importance of nozzle size when it comes to 3D printing. The nozzle is that tiny opening on your 3D printer’s extruder that is responsible for laying down the melted plastic filament layer by layer to create your print. While it may seem insignificant compared to more prominent components like the hotend or print bed, the nozzle plays a critical role in determining print quality, speed and overall performance.

In this comprehensive guide, I will explain what a 3D printer nozzle is, the different nozzle sizes available, how nozzle size affects your prints, and tips on choosing the right size nozzle for your specific application. Whether you are new to 3D printing or a seasoned pro, read on to gain a deeper understanding of this vital but often overlooked component.

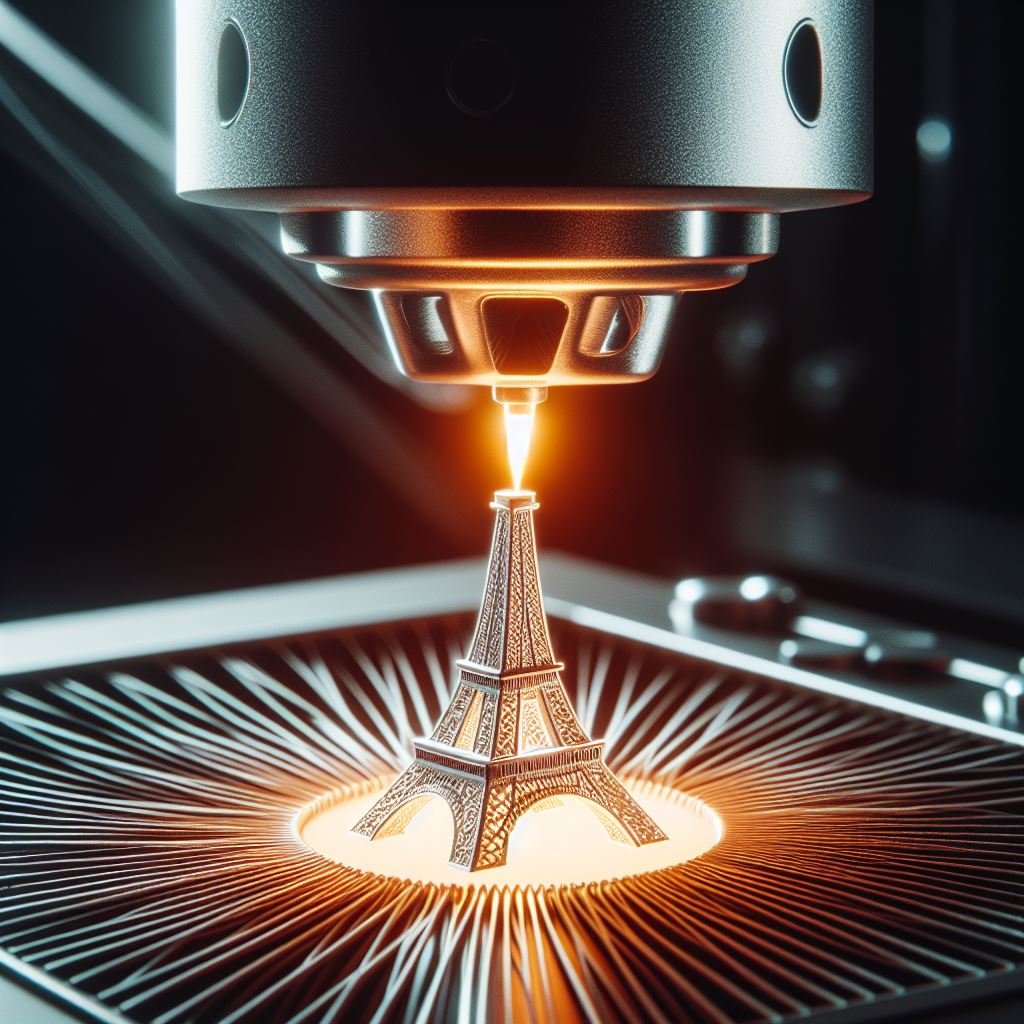

What is a 3D Printer Nozzle?

The nozzle is the business end of your 3D printer’s extruder system. It is a small component, usually made of wear-resistant brass, steel or ruby, that is responsible for extruding the heated plastic filament onto the print bed. The nozzle opening has a cylindrical shape and is precisely machined to a specific inner diameter, typically between 0.2mm to 1mm.

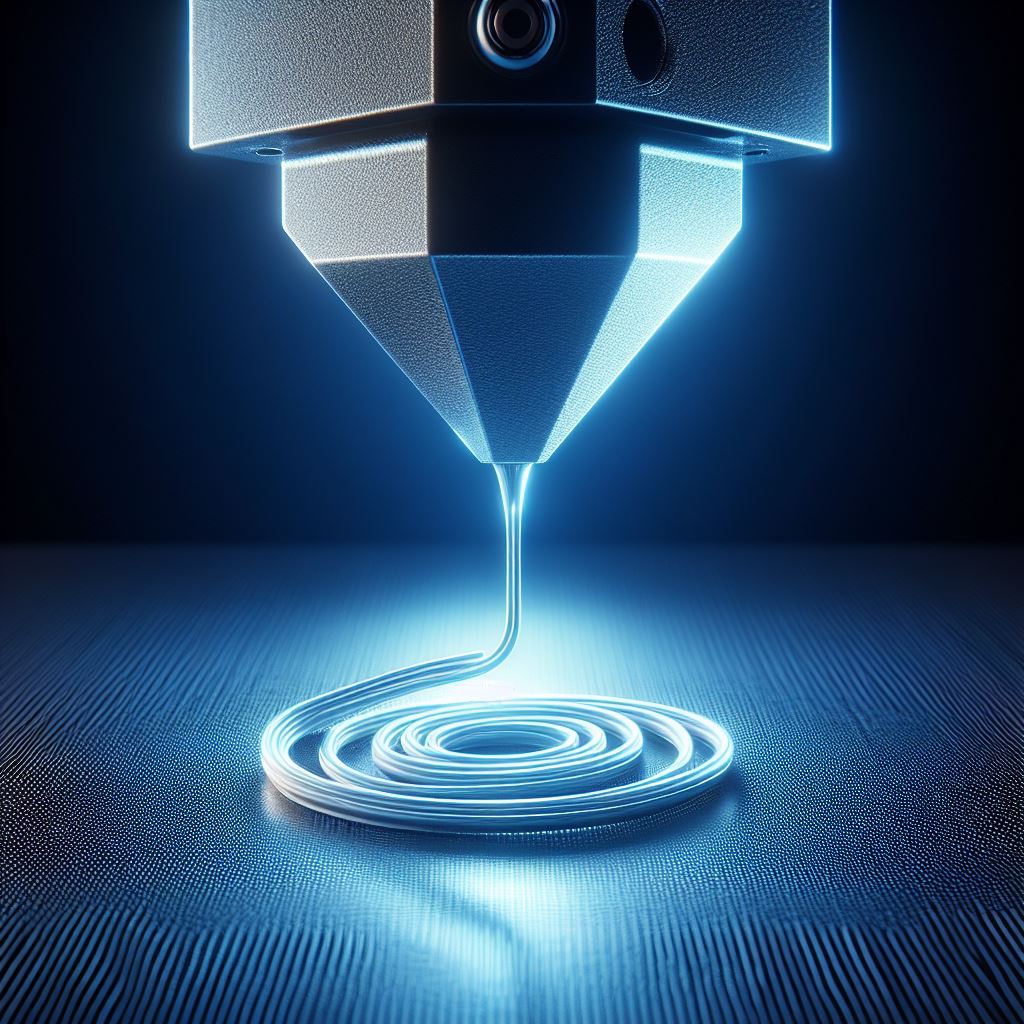

As the plastic filament is fed into the extruder, it is heated to a molten state in the hotend chamber before being forced out of the nozzle opening to create each layer of your print. The size of this opening determines the width and precision of the extruded plastic tracks for that layer. After one layer is laid down, the print head moves up vertically and lays down the next layer on top, gradually building up the print.

So in summary, the key functions of a 3D printer nozzle are:

- Extruding molten plastic to deposit material

- Controlling flow rate and material volume dispensed

- Determining bead width and X/Y resolution of print

The nozzle opening is also referred to as the bore or aperture. Nozzles come in a range of standard sizes but 0.4mm is the most common diameter for general use.

Why Nozzle Size Matters

Nozzle size matters because it has a significant influence on the final print resolution, quality and appearance. It also affects the printing speed and susceptibility to clogs. Selecting the right nozzle diameter requires balancing these critical factors for your particular application. Here’s a more detailed look at why it matters:

Print Resolution and Details

The smaller the nozzle diameter, the finer the print resolution and ability to reproduce intricate details on the X and Y axes. A 0.2mm nozzle paired with a 0.1mm layer height allows extremely high 14 micron resolution in the Z-axis for remarkably clear prints.

However, minimum nozzle sizes are limited by the particle size of colorants and other additives in the plastic filament. Anything below 0.2mm risks frequent clogging. Standard 0.4mm nozzles offer a good balance of resolution without excessive clogs.

Print Speed

Wider nozzle diameters allow greater flow rates, enabling much faster print speeds, so a 0.8mm nozzle can print twice as fast as a 0.4mm. But the trade off is lower resolution and visible layer lines on prints. Anything above 0.8mm is typically too wide for quality prints.

Part Strength

Research shows that smaller nozzle diameters paired with thinner layer heights produces stronger 3D printed parts. This is because thinner layers bond better leading to improved interlayer adhesion.

Surface Finish

The stepped layered structure of 3D prints can result in visible striations on sloping and curved surfaces. Using a smaller nozzle paired with thin layer heights minimizes this staircase effect for optimally smooth surface finishes.

Clogs and Jams

Smaller nozzles are inherently more prone to material clogs and jams. This may mandate higher printing temperatures and non-abrasive filaments. Larger diameters are virtually clog-proof.

As you can see, nozzle size has wide ranging effects encompassing minute details to overall print quality and speed. Finding the ideal size means prioritizing application requirements and striking the right balance of properties.

Different Nozzle Sizes and Types

3D printer nozzles come in a range of metric sizes to suit diverse applications. While diameters can theoretically range from 0.1mm to 2mm, common sizes include:

0.2mm Nozzle

A 0.2mm nozzle produces exceptionally high 25 micron resolution prints with very fine details. But the downside is a high tendency to clog and strict requirement for non-abrasive filaments. This makes 0.2mm best suited for tiny precision prints like miniatures.

0.25mm Nozzle

The 0.25mm nozzle strikes a balance between fine 0.05mm layer height resolution and reduced clogging over 0.2mm sizes. It allows printing of detailed surfaces, intricate patterns and objects below 10mm scale. It’s great for detailed prints like jewelry and architectural models.

0.3mm Nozzle

A 0.3mm nozzle offers a midpoint option between standard 0.4mm and fine detail 0.25mm nozzles. You can still produce sharp corners and print small fonts legibly while using thicker layers for faster prints. It’s a good balance between speed and resolution.

0.4mm Nozzle

The 0.4mm nozzle is generally considered the best all-round performer for most prints and materials. It offers a versatile combination of good print speeds, resolution, surface finishes and reduced clogging over smaller diameters. It’s especially suitable for common materials like PLA, PETG and ABS.

0.5mm Nozzle

A 0.5mm nozzle widens things up for faster, heavier duty printing. The slight extra width allows around 30% faster print speeds over 0.4mm while still retaining reasonable detail. It also resists clogs well making it good for composites. The trade off is visibly thicker layers.

0.6mm – 1.0mm Nozzles

Nozzles in this range offer the fastest printing but layer lines are quite visible. They are best for printing very large low detail items faster. Surface finishes also benefit from a smoother look at this scale. They work well with softer flexible materials too. Anything above 1.0mm is extremely fast but resolution suffers too much for most applications.

So in summary, it’s about choosing small for utmost detail, standard 0.4mm for typical use and wide for maximum speed.

How to Choose the Right Nozzle Size

I recommend considering the following key factors when deciding on nozzle size for your prints:

Type of Print

Consider the scale and nature of objects you’ll be printing. Tiny detailed miniatures with fine features suit small nozzles around 0.25mm. Larger general prints like prototypes and decorative objects are best with 0.4mm. Big low detail decorative pieces can use wider 0.6-1mm nozzles.

Filament Materials

Check your filament specs and printer capabilities. Non-abrasive standard materials like PLA, PETG and ABS offer the most flexibility and allow very small nozzle sizes. Exotics like wood, metal or carbon fiber composites may mandate wider nozzles from 0.5mm up to resist clogging.

Speed vs Quality Priority

Determine whether print speed or resolution is more important. Wider nozzles prioritize faster printing while smaller ones do the opposite by enhancing detail and finish at the cost of speed. Select size based on your application priority.

Experimental Testing

Don’t be afraid to experiment with different nozzle sizes for your printer. Running test prints will give you a real-world feel for how nozzle size impacts your particular models. Analyze the prints and choose the best size.

While tiny details demand tiny nozzles and maximum speed calls for wide ones, 0.4mm works great for most prints. Consider specialty nozzle sizes for niche applications like miniatures or fast concept models.

Changing Nozzles and Maintaining Performance

Here are some best practice tips on changing 3D printer nozzles and maintaining performance:

Ensure Compatibility First

Before installing any replacement nozzle, check that your printer model can accept the specified nozzle diameter without impacting the X-carriage clearance or print quality. Most printers can fit nozzles up to 0.6mm but confirm first.

Verify Dimensional Accuracy

The new nozzle must feature extremely precise inner diameter consistency with tight machining tolerances for reliable performance. Reputable nozzles provide quality certificates verifying critical dimensions. Cheap clones can suffer from subpar manufacturing.

Perform PID Tuning

Anytime you install a replacement nozzle, carry out PID tuning of the hotend to calibrate optimal temperature control parameters. Different material compositions and thermal properties can impact this. Tuning ensures you print at the right temperatures.

Adjust Filament Flow Rates

Different inner diameters require different volumetric filament flow rates even at the same print speeds. It’s important to finely tune extruder E-steps and flow multipliers in your slicer to get clean precise extrusions perfectly matched to the nozzle.

Modify Slicer Settings

Tweak key slicer settings to best suit the new nozzle’s properties:

- Layer heights

- Print speeds

- Cooling fan

- Retraction distances

- Ooze control

Dialing in optimized slicer settings is critical for clean prints with new nozzles.

Assess Adhesion

Test bed adhesion early on. The first layer squish and consistency can vary significantly between different nozzle diameters. You may need to adjust build plates, heights, adhesives or temperatures to accommodate the new nozzle.

Start off by printing benchmark validation models to assess the real world performance of your new nozzle. Analyze the results before moving on to important prints. Handle narrow nozzles carefully to avoid bending or burrs around the opening.

Specialty Nozzle Tips and Variants

While standard cylindrical brass nozzles cover most printing needs, specialty variants exist offering enhanced properties:

Hardened Steel Nozzles

Extremely durable hardened steel nozzles allow printing highly abrasive composite filaments wearing down brass in just days. They also handle ULTEM and PEEK filaments requiring 400°C hotends.

Ruby Nozzles

Ruby nozzles are extraordinarily wear resistant making their bore diameters highly dimensionally stable over time. This allows unparalleled consistency over thousands of hours printing abrasive filaments. They also resist corrosion and acids.

Coated Nozzles

Specialized surface coatings like nickel-plating or diamond-like carbon coating (DLC) applied to nozzle bore walls provides protection against chemical corrosion and abrasive wear while improving durability.

Custom Shapes

Exotic custom nozzle shapes like conical, elliptical or rectangular (slotted) in place of standard cylindrical round ones allows manipulating the extruded bead for special techniques or unique textures.

The standard cylindrical brass nozzle meets most needs but more demanding filaments may justify upgrading to premium specialty nozzles for optimal results.

At warhammeruniverse.com, we also have a youtube channel with other helpful informational guides or interesting videos related to 3D printing and miniatures. Be sure to check it out for supplemental content on getting the most out of your printer.

Key Takeaways on Nozzle Size Selection

To wrap up, here are my key takeaways on choosing the right nozzle size:

- Nozzle size significantly influences print resolution, speed and quality

- Smaller nozzles enable remarkably fine details but risk more clogs

- Larger nozzles print faster but have visibly lower resolution

- 0.4mm is the best all-round size for most prints

- Consider print goals, filament properties and real-world testing

- Always confirm compatibility and tune slicer settings for new nozzles

I hope this guide has helped explain why nozzle size matters and how to select the diameter that best suits your particular 3D printing application. Properly optimizing this simple but vital component of your printer can make a world of difference in your print quality, speed and overall user experience. Please feel free to reach out with any other questions!

Related Articles

Find the top 3D printers for miniatures in 2024 – compare 15+ leading options for all budgets weighing print quality, resolution, speed and value.

Get definitive answers on 2024 laws for 3D printing miniatures surrounding Warhammer IP and copyright permissions for personal and tournament use.

Learn techniques for preparing miniatures – master cleanup, priming, painting and finishing tabletop-ready 3D printed models.

Get total clarity on full costs for printing warhammer armies – calculator covers printer, resin/filament, paints, 3D models and army size factors.

Compare starter 3D printer options for beginners on affordability, ease of use and print quality considerations – great for hobbyist newcomers.

Apply fundamental 3D printing techniques as a beginner – tackle test prints then master software, model prep, painting etc.

Get key strategies for success when 3D printing tricky Warhammer miniatures – supports, orientation, bed adhesion and more.

Master end-to-end 3D printing workflows for miniatures from robust prints to vibrant, long-lasting painting and preservation.

Learn pro techniques for painting miniatures to achieve vibrant, ultra durable tabletop models ready for gameplay and display.

Discover budget kitbashing techniques for easily customizing Warhammer miniatures using parts from various sources.