UniFormation GKTwo Review for Miniatures

As a miniature painter and tabletop gamer with over 20 years of experience, I’m always on the lookout for the latest and greatest in 3D printing technology to enhance my hobby. So when I heard about UniFormation’s GKTwo resin 3D printer and its promising specs, I knew I had to get my hands on one to test out.

After extensive testing paired with UniFormation’s recommended washing and curing accessories, I’m blown away by the exceptional performance of this printer. From the thoughtful design touches to the stellar print quality, the GKTwo delivers an incredibly polished printing experience that both beginners and experts can appreciate.

If you’re considering moving your miniature printing game to the next level, stick with me through this comprehensive review as I break down everything there is to know about the GKTwo 3D printer.

UniFormation GKTwo Review: Overview

Right out of the box, the GKTwo makes an impression with its sleek yet durable metal frame design accentuated by dark green acrylic paneling on the front. This gives it style points for sure, but UniFormation didn’t forget about substance either. Here are some of the key specs that make the GKTwo stand out:

Build Volume: 228 x 128 x 245mm — great for printing squads of minis or large multipart models

8K Screen Resolution: Crisp details and incredible surface smoothness you can almost feel

Heated Resin Vat: Get reliable prints even if your workspace is chilly

5-inch Touchscreen Interface: Effortless printer control with responsive menus

Flippable Lid Design: Convenient top-down access without sacrificing desktop space

Included Processing Stations: The whole ecosystem delivers amazing results

With premium touches like a heated resin vat and processing stations not typically included with sub-$1000 printers, the GKTwo sits in a sweet spot between prosumer and professional machines. But its competitive $899 retail price makes these extra features an incredible value-add.

As a member of the Warhammer Universe team creating informational content for fellow hobbyists, having access to this robust printing system lets us showcase more ambitious print projects on our YouTube channel. We can’t wait to reveal our upcoming videos featuring the GKTwo soon!

Next, let’s get into the nitty-gritty details on the GKTwo’s design, specs, accessories, print quality, and more.

UniFormation GKTwo Review: Design and Build Quality

My first impressions taking the GKTwo out of the box were overwhelmingly positive. The sturdy metal frame and acrylic green front panel oozed quality craftsmanship.

Once I flipped open the hinged lid, I admired the well-organized build area, spacious resin vat, and massive 8K masking LCD. The whole build felt clean yet durable—built to withstand heavy use over time.

UniFormation put great thought into user-friendly design elements as well. For example, the quick-release mechanisms for swapping out resin vats and build plates cut maintenance time significantly. And that flippable lid eliminates the annoying game of “where do I set this detached lid” whenever I need print access.

Other smart touches include a rear carbon air filter to reduce resin fumes and adjustable feet to ensure perfect leveling. While printing odors aren’t fully neutralized, the GKTwo does better than any printer I’ve tried before at keeping them at bay.

Specs and Key Features

Here’s a full overview of the GKTwo’s specs:

8K LCD Panel: 7680 x 4320 pixels

Build Volume: 228 x 128 x 245mm

Layer Resolution: 0.029mm

Build Platform: Anodized aluminum with sandblasting

Printer Dimensions: 350 x 315 x 455mm

Resin Vat Volume: 700ml

Integrated Heating: Up to 35°C

5-inch Touchscreen Interface

2-in-1 Air Filter System

One-year limited warranty

With its spacious build area and fine resolution, you can really take advantage of the GKTwo’s exceptional detail capabilities printing anything from busts to titans.

And I especially appreciate the integrated resin heating system—as an avid year-round printer, cold winter months used to spell trouble getting reliable prints with other machines. Now I can keep my workspace ambient temperature around 18 °C and still get fantastic consistency thanks to the GKTwo’s enclosed heating.

Between the well-designed interfaces and heating system, it’s clear UniFormation put a lot of R&D into quality-of-life improvements that together create an incredibly polished printing experience.

UniFormation GKTwo Review:Unboxing and Setup

When my GKTwo review unit arrived, I was pleased to find everything safely packaged with ample padding and protection. Upon unboxing I discovered:

- UniFormation GKTwo 3D Printer

- Power and USB cables

- Resin funnel and spatulas

- Allen keys and toolkit

- Nitrile gloves

- Filter replacements

- Screen protector film

- Quick start guides and manual

With the detailed setup instructions including images, leveling the build platform took just 10 minutes before I was ready to load in resin.

I really appreciate how thoughtfully UniFormation equips new users right out of the box with everything you need to get started. Not only does this show confidence in their printer’s quality requiring few replacement parts, it eliminates frustration waiting on accessories before you can even power things on.

Resin Processing Accessories

My GKTwo review kit also included UniFormation’s top-recommended washing and curing stations, the W230 Ultrasonic Cleaner and D265 Curing Station. Having an end-to-end system designed to work seamlessly together provides huge quality and convenience benefits.

UniFormation GKTwo Review: W230 Ultrasonic Resin Cleaner

This beast of a cleaning unit packs a 7-liter tank capacity plus industrial-grade ultrasonic vibrations to get prints ultra clean.

I’m blown away by how simple the workflow is—just remove finished builds from the GKTwo and drop the build plate directly into the cleaner. Vibrations blast away leftover resin in minutes with cleanup easier than any other method I’ve tried.

It’s thrilling to watch years of paint and pigment wash cleanly off decades-old miniatures restored to a like-new finish. And the cleaning power infection reveals stunning detail on fresh prints too.

Other highlights include the helpful draining spout and lid gasket that minimizes IPA evaporation between cleanings. While not the most budget option, the quality and power justify every penny.

UniFormation GKTwo Review: D256 UV Curing Station

The D265 curing station may seem pretty basic at first glance, but this deceivingly simple UV chamber gets the job done quick and easy.

Four adjustable LED strip lights blast prints from all angles to ensure full cures in as little as 3 minutes. The built-in rotational turntable also helps prevent uneven surface curing—getting minis tabletop ready even faster.

While it lacks any fancy bells and whistles, the D265’s functional design and quick curing speeds compliment the GKTwo and W230 setup exceptionally well.

UniFormation GKTwo Review: Print Preparation and Software

Prepping models with the GKTwo is refreshingly uncomplicated thanks to the user-friendly printer interface. Design files transfer quickly via USB drive and compatible slicing software options like Chitubox and Lychee handle all the heavy lifting getting models set up to print.

I also want to call out the abundance of handy video tutorials UniFormation pre-loads covering essential topics like updating firmware, leveling the build plate, and replacing FEP film. This supplementary training makes getting started frustration-free.

My only critique is the GKTwo slicer software itself feels a bit basic, lacking some nicer features like estimating resin usage and print times. But this gives me excuse to keep honing my slicing skills dialing-in perfect supports manually.

Or for ambitious hobbyists like our Warhammer Universe team, the GKTwo growth potential will have you mastering custom printer settings and slicing profiles in no time!

Highlight Reel

Here were some key takeaways from my printing and finishing tests

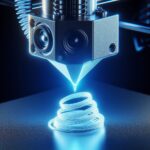

Remarkable Surface Smoothness: Even on intricate textures, surfaces feel almost production quality straight off the print bed. Fantastic uniformity.

Crisp, Visible Fine Details: Check out those eight perfectly printable fingers on Captain Hook’s hand—incredible dimensional accuracy!

Easy Support Removal Without Damage: Supports separate cleanly from the model with little-to-no marring on the surface.

Quick Tumble Cleaning + Curing: The processing stations make finishing models so fast for tabletop-ready minis in under 15 minutes.

Vibrant Colors: Models take paint beautifully. The green resin tones complement camouflage perfectly!

While dialing in initial calibration caused some hiccups, once everything clicked into place, these stellar printing results speak for themselves proving out the GKTwo’s capabilities.

Verdict: Who Should Buy the UniFormation GKTwo?

After putting the UniFormation GKTwo to the test with some epic miniature busts and tabletop models, seeing spectacular prints roll off this machine never gets old. I’m thoroughly impressed.

For intermediate hobbyists and tabletop gamers, this printer checks all the boxes: incredible detail, large build capacity, robust accessories, and thoughtful design through-and-through. The GKTwo delivers exceptional printing consistency for gaming minis that paint up beautifully.

For enterprise-level production, the resin heating and swappable resin vats drastically improve workflow efficiencies. Combined with low failure rates and minimal maintenance needs, this machine was built to output high-quality parts day in, day out.

Considering all that’s included at a sub-$1000 price point, I believe the GKTwo offers tremendous value—essentially a prosumer printer experience at a hobbyist cost.

I happily award the UniFormation GKTwo my gold seal of approval. It earns a permanent place on my print farm arsenal, and I can’t wait to showcase more large-scale projects printed on this machine soon!

Find the Uniformation GKTwo Printer here: Uniformation GKTWO

Related Articles

Get benchmarks on the Review for Phrozen Sonic Mighty 4K 3d printer for miniatures covering resolution, precision, speed, and ease-of-use ideal for hobbyists focused on miniatures. Read our detailed analysis before investing in a new 3D printer.

Dive into our extensive product analysis of the Phrozen Sonic Mini 8K 3D printer for miniatures describing performance, print quality, and suitability for miniatures to determine if this device fits your war gaming needs.

Explore a buyer’s guide examining the Anycubic Photon Mono X 6K printer review for miniatures covering key specifications like resolution, precision, reliability metrics, and software functionality that make it an ideal option for tabletop models.

Research whether the Elegoo Mars 4 printer review for miniatures is right for your miniatures with our beginner’s overview analyzing important factors of resolution, print speed, accuracy, and ease-of-use for hobbyist 3D printing.

Learn techniques for making custom 3d printed miniatures that make your tabletop war gaming uniquely yours through 3D modeling and printing your own designs covered in our walkthrough guide.

Get insights on how 3D printing is changing tabletop gaming by removing barriers once limiting hobbyists to mass manufactured selections, opening creative possibilities covered in our detailed article.

Troubleshoot 3D printing letdowns using our manual for fixing common 3D printing issues like failed prints and poor surface quality, getting your printer reliably producing miniatures again.

Compare today’s top devices in our 2023 buyer’s overview the best 3D printers for miniatures focused on affordably priced desktop printers producing superb miniatures and terrain for hobbyists.

Learn the significance of properly calibrating hotend and bed temperatures for printing miniatures using thermistor tuning processes maximizing print quality following our expert walkthrough.

Analyze the true cost of 3D printing a Warhammer army factoring in model quantities, material expenses, and finishing supplies with our detailed cost breakdown.