Best Guide to 3D Printer Temperature Calibration for Best Print Quality

As an avid 3D printing enthusiast and member of the warhammeruniverse.com team with over 20 years of hobby experience, I am passionate about helping others achieve the best possible print quality. Properly calibrating your 3D printer’s temperature settings is crucial but can seem intimidating to newcomers. Never fear! In this comprehensive guide, I will walk you through everything you need to know about temperature calibration using a handy temperature tower model. Ready to level up your printing game? Let’s get started!

The Importance of Temperature Calibration

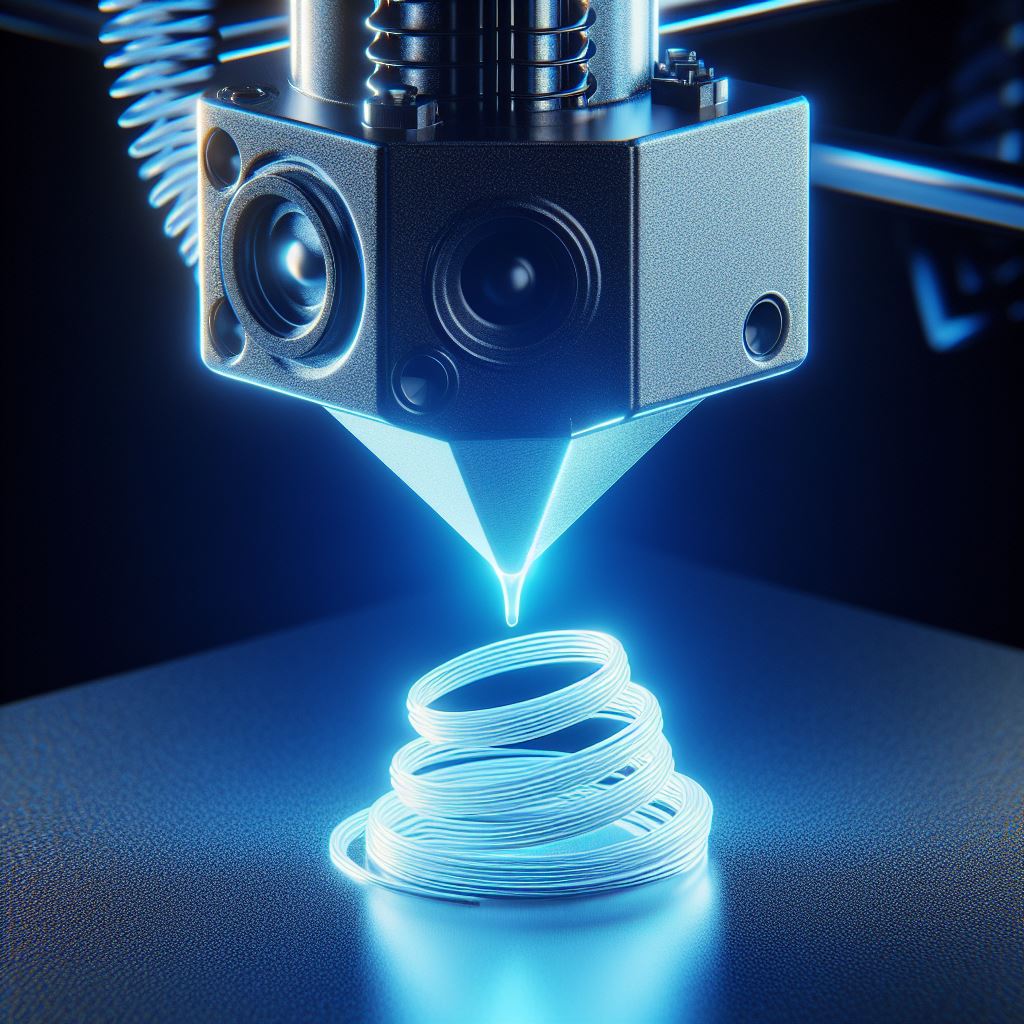

Before we dive into the specific steps, it’s helpful to understand why temperature calibration matters in the first place. In short, every 3D printer filament has an optimal temperature range that produces the best layer adhesion, detail resolution, and surface finish. Print too cool and layers may separate. Too hot and models can become stringy or lose fine details.

The catch is that the perfect temp can vary based on your specific machine, nozzle, hotend design, filament manufacturer specs, ambient room temperature, printing speed, and even color pigments. Yikes! The good news is that temperature towers provide an easy way to test a range of temps to pinpoint what works best. Think of it as a mini science experiment for tuning your printer!

Choosing the Right Temperature Tower STL

Okay, let’s start by downloading a temperature tower STL file. My go-to is this great model by Jan Petersen which has evenly spaced sections and includes a stringing test. The gradual shape also makes it easy to assess bridging performance.

I’d recommend testing a range of 190°C to 215°C for PLA, 210°C to 240°C for PETG, and 220°C to 250°C for ABS. These serve as good starting points though feel free to extend 10° above or below if needed. Pro tip: check your specific filament’s packaging for the manufacturer’s suggested range too.

Slicing and Printing Your Tower

Once you have your tower STL downloaded, it’s time to slice it up and get printing! The frustrating part is that not all slicers have native support for adjusting temperatures at different heights. So you may need to get handy with some manual GCode tweaking to insert the changes. Let’s walk through the steps for popular slicers:

Simplify3D:

Luckily, Simplify3D makes things easy with their Variable Setting Wizard under Tools > Variable Setting Wizard. Just split your tower model into sections starting at 12mm and every further 10mm. This will create separate processes that you can define with different temperatures under the Temperature tab.

Cura:

No built-in variable temp controls here either. Instead, check out the “Post Processing” section under Extensions > Modify GCode. Look for the ChangeAtZ script. This lets you specify a height for temp changes. Add multiple scripts to set all your desired testing points across the tower.

Slic3r:

Currently no support for variable temp settings in Slic3r. You’ll need to modify the exported GCode manually as explained next.

Manually Editing GCode:

If your slicer is being stubborn, don’t worry, editing the GCode by hand is totally doable! Open your exported file in a text editor like Notepad++. The key is finding a specific height change command to insert a temperature adjustment beforehand.

Search for “G1 Z12” for the 12mm section for instance. Right BEFORE this line add:

M104 S215 T0

T0 specifies extruder 1 and S defines the temp in Celsius. Make sure to save your file before printing!

Analyzing Tower Results

Alright, with your temperature tower finally printed, here comes the fun part – assessing the results! Closely check layer adhesion in the overhangs and bridges by trying to break sections apart. Also pay attention to stringing across ranges.

The optimal temp is generally the lowest you can print before layers start visibly separating while still maintaining good bridging. Don’t worry if the entire tower looks pretty similar and uniform. That likely just indicates a high quality filament! In that case, start middle of the range.

Refining Based On Priorities

Something to note is that temperature targets can change based on your print priorities, whether that is maximizing mechanical strength versus print appearance. Higher temps generally increase layer bonds but may create more visible strings or lose fine details.

If focusing on visual quality, examine small features and overhangsclosely on your tower. For better inter-layer adhesion, actually test specimen samples from each temperature with physical stress or pulls. In some cases you may find a “sweet spot” temperature balancing both needs well.

Beyond just success or failure of the tower, also pay attention to the overall glossiness versus matte nature of surfaces which can influence perceived color. This can help you better match the visual style you are going for.

Understanding Other Printing Temperature Impacts

While a properly tuned temperature is critical for print success, it can also directly impact other aspects of your printer hardware if set too extreme in either direction. Getting familiar with the potential downsides can help you narrow into the ideal range safer. Let’s review a few:

Too Hot:

- More chance of filament “oozing” leading to strings

- Corners may curl upwards as cooler layers shrink

- Small details becoming blobby

- Difficulty detaching same-material print supports

- Possible heat creep issues over time

Too Cool:

- Layers separating or splitting

- Gaps between outer walls and infill

- Clogs from filament struggling to melt

- Can’t fill space between layers fast enough

Hopefully understanding the many tradeoffs helps illustrate why taking the time to test temperatures carefully matters!

Advanced Filament-Specific Calibration

Alright, so at this point hopefully you have mastered the art of temperature tower analysis! As one final pro tip, I recommend re-running calibration every time you switch filament rolls.

While a quality filament should meet the manufacturer specs, there is always some real-world variation in average diameter along the length. This can change the optimal temp slightly.

Here is a great filament calibration routine:

- Physically measure diameter in multiple places with calipers

- Update average into your slicer profile

- Print another tower to confirm new ideal temperature

- Consider drying materials like ABS for optimal layer adhesion

Conclusion

And there you have it – everything you could possibly need to know about fine-tuning temperatures on your 3D printer for absolutely perfect prints! Our warhammeruniverse YouTube channel also covers printer calibration topics in more detail with video examples. Let us know if this guide helps you take your results to the next level!

Related Articles

- Explore the Best 3D Printing Tactics

- Dive into our comprehensive guide covering tactics to boost your battlefield success. Discover top-notch strategies for miniature enthusiasts on The Best 3d Printers for Warhammer

- Mastering Bed Adhesion Problems: A How-To

- Troubleshoot and conquer 3D printer bed adhesion issues with our guide on problem-solving. Enhance your printing journey with expert troubleshooting tips.

- Crafting Unique Miniatures: A Beginner’s Guide

- Embark on a creative journey with our guide on how to create custom miniatures. Perfect for beginners, this guide unlocks the world of personalized figurines.

- Prime and Paint Like a Pro: Beginner’s Edition

- Elevate your miniature painting skills with our beginner-friendly guide on how to prime and paint 3D printed miniatures. Uncover techniques to bring your creations to life.

- 3D Printing Warhammer Armies: A Comprehensive Guide

- Delve into the realm of Warhammer armies with our detailed guide on 3D printing Warhammer miniatures. From printing to painting, preserve your army with expert advice.

- Nozzle Size Mastery: Choosing the Right Fit

- Navigate the significance of nozzle size in 3D printing. Discover why nozzle size matters and how to make the perfect choice for your printing endeavors.

- Begin Your 3D Printing Journey: A Guide

- Ready to start printing your own miniatures? Our guide on getting started with 3D printing is perfect for beginners. Unlock the secrets of creating your unique figurines.

- Pro Tips for 3D Printing Warhammer Figures

- Enhance your 3D printing skills with our pro tips for 3D printing Warhammer figures. Elevate your craft with valuable insights and techniques.

- Discover, Print, and Play: A Miniature Guide

- Explore the world of Warhammer with our guide on how to find and print miniatures. Uncover the joy of discovering and printing your favorite models.

- Legal Insights: 3D Printing Warhammer in 2024

- Stay informed on the legal aspects of 3D printing Warhammer. Our guide on is 3D printing Warhammer legal in 2024 provides essential information for hobbyists.