How to Fix Printing Overhangs and Bridges in 3D: A Guide for Stable Structures

As an enthusiast 3D printer with over 20 years of experience printing miniatures, I often get asked by fellow hobbyists how to print tricky overhangs and bridges successfully without adding messy support structures.

Overhangs and bridges represent some of the biggest challenges when it comes to FDM 3D printing. But with the right techniques and slicer settings, you can print beautiful, gravity-defying structures perfectly every time.

In this comprehensive guide, I’ll share everything I’ve learned about achieving stable, high quality overhangs and bridges on desktop FDM printers. I’ll explain what overhangs and bridges are, why they are difficult to print, and provide actionable advice on how to address them in your designs and prints.

Whether you’re new to 3D printing or a seasoned veteran, you’re sure to pick up some useful tips here. The team at Warhammer Universe and I have put together this guide after years of trial and error to help you avoid the same pitfalls in your printing journey.

What is an Overhang?

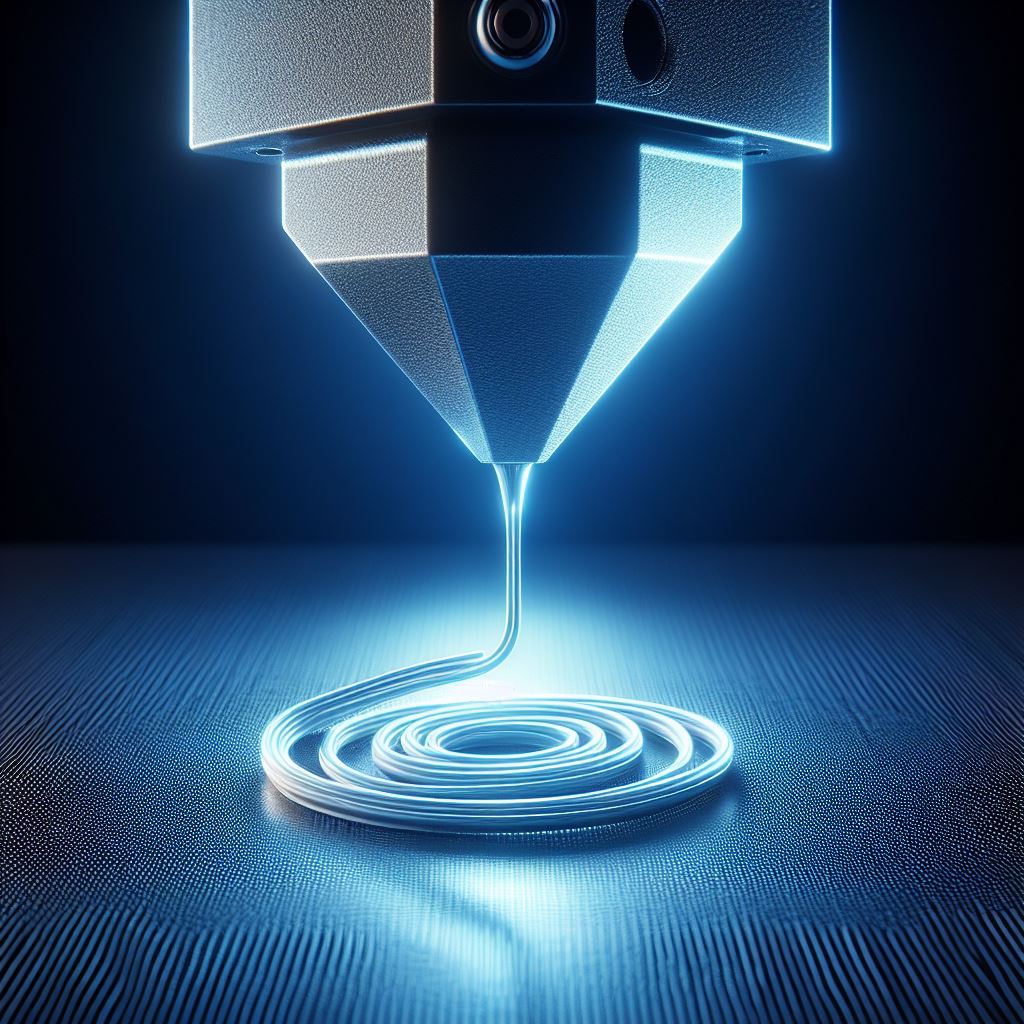

An overhang in 3D printing refers to any section of a print that has no support underneath. This includes horizontal protrusions, bridges between vertical walls, or internal cavities within a print.

Overhangs are problematic because as each new layer is printed, there is nothing below to keep it in place. The plastic extruded by the nozzle has nothing to adhere to except the previous layer. As more layers build up, eventually the weight causes overhangs to droop, sag and even snap off entirely.

The key factors that determine if an overhang will print successfully are the angle and length relative to supported areas:

– Angle

In general, a 45 degree angle is the maximum that can be printed without supports before overhangs start to destabilize. The lower the angle, the more shear force the new layer exerts on the previous one. Exceeding 45 degrees often results in drooping or collapsed overhangs.

– Length

The longer an overhanging section protrudes, the more weight it accumulates as additional layers build up. Long, horizontal protrusions tend to destabilize and droop even at shallow angles. Shorter extensions have a higher chance of printing successfully.

Next we’ll look at bridges, which represent a special subset of overhangs.

What are Bridges?

Bridges refer to overhangs that span a gap between two or more vertical walls or surfaces. With bridges, tension is maintained between anchor points on both sides, helping stabilize horizontal protrusions.

Well tuned printers can successfully “bridge” gaps up to around 5mm without supports. However, longer bridges accumulate more sag and destabilize similar to regular overhangs. Excessively long bridges will still eventually collapse, even with perfectly dialed in settings.

Now that you understand what overhangs and bridges are, let’s look at some ways to address them.

Minimizing Overhangs in Design

The easiest way to achieve stable overhangs is to avoid them where possible. When designing models for 3D printing, consider the following:

– Print Orientation: Flipping or rotating your model can eliminate overhangs entirely. Print upright surfaces flat along the bed rather than sideways.

– Split Model: Break your original model into multiple components with fewer overhangs, then assemble after printing.

– Chamfers and Curves: Use sloped edges instead of sharp corners to gradually change angles.

– 45 Degree Rule: Adjust protrusions and bridges to 45 degrees or less when feasible.

Now let’s move on to printing techniques for models where overhangs are unavoidable.

Printing Techniques for Overhangs

When overhangs can’t be avoided through design changes, special allowances must be made during printing. Here are some effective techniques:

1. Supports

Support structures printed underneath overhangs are the most reliable way to reinforce them. Towers, walls or branch-like supports prevent drooping. Support generation can be automated in slicing software. Manually placed supports may also help.

2. Bridging

For bridge-style overhangs between vertical surfaces, try disabling supports and relying on tension alone. Start with bridge lengths under 5mm. Enable bridge settings in your slicer.

3. Experimental Methods

More advanced users can try experimental techniques like arc overhangs or multi-axis printing to print some geometries without supports. These methods involve custom hardware or software modifications.

In addition to techniques, adjusting your print settings properly also plays a huge role.

Slicer Settings for Better Overhangs

To give your overhangs the best chance of printing cleanly without deforming, use these print settings:

– Lower Print Speeds significantly to 5-10mm/sec for better cooling

– Reduce Temperature to the lowest reliable extrusion temp for your filament

– Max Cooling Fan speed for rapid solidification

– Thinner Layer Height means less droop per layer. Use adaptive layer heights if possible

– Dry Filament is essential. Moisture creates bubbles that weaken overhangs

Best tips for errors

Material Considerations

The type of filament used can impact overhang performance. Materials like PETG are more prone to sagging and stringing. PLA generally performs better for overhangs. Try different materials and see which ones bridge the best on your printer.

Hardware Upgrades

Upgrading to an all-metal hotend or direct drive extruder can enhance precision, allowing better overhangs. Improving part cooling with ducting mods or additional fans also helps overhangs solidify quicker.

Exotic Overhang Printing

Some advanced methods like printing tiny supported micropillars or tree supports rich in B branches shows promise for easier support removal. Combining this with soluble interface layers means less sanding.

Post Processing Overhangs

Careful post processing work can salvage even the most disfigured of overhangs. Sanding, filling, priming and painting can hide a myriad of printing sins!

Slicer Support Settings

Explore using interface layers, thicker base supports, alternate support patterns or tapering angle to ease support removal on tricky organic shapes and deep cavities.

Conclusion

With the right techniques, orientation, settings and well tuned printer, you can print some incredibly ambitious geometries. But when in doubt, reach for those supports! They exist for good reason.

I hope this guide has given you a better grasp of overhangs and bridges, and how to approach printing them. As always, feel free to check out our YouTube channel for more tips and tricks for 3D printing miniatures.

Related Articles

- Mastering Speed and Quality: Uncover tactics for 3D printers to enhance battlefield success. Explore our comprehensive guide, revealing the best tactics to strike the perfect balance for your 3D printed models.

- Crafting Warhammer Figures: Dive into tips for 3D printing Warhammer figures. This guide, tailored for beginners, explores the art of creating intricate Warhammer figures. Unleash your creativity and bring your miniatures to life with expert advice.

- Optimizing Costs in 2024: Learn how much 3D printing Warhammer miniatures and armies cost. Our guide breaks down the expenses, providing insights to help you plan and budget for your Warhammer hobby in 2024.

- Perfecting the First Layer: Unlock the secrets of getting a good first layer in 3D printing. Elevate your printing game with our guide, ensuring a solid foundation for flawless Warhammer models right from the start.

- Nozzle Longevity Tactics: Combat nozzle wear and tear in 3D printing. Discover prevention strategies and solutions to keep your nozzles in top condition, ensuring consistent and high-quality Warhammer prints.

- Choosing the Best Printers: Navigate the world of 3D printers for miniatures. Our guide simplifies the selection process, helping hobbyists find the ideal printer for their Warhammer projects.

- Temperature Calibration Mastery: Dive into the best guide for 3D printer temperature calibration. Elevate your print quality with expert insights on temperature control, ensuring optimal results for your Warhammer creations.

- Troubleshooting Bed Adhesion: Solve 3D printer bed adhesion problems like a pro. Our troubleshooting guide provides essential tips to ensure your Warhammer miniatures adhere flawlessly to the print bed.

- Sculpting and Printing Adventures: Embark on a creative journey with creating custom miniatures with 3D sculpting and printing. Unleash your imagination, sculpt unique Warhammer miniatures, and bring your creative visions to life with our beginner-friendly guide.