Nozzle Wear and Tear When 3D Printing – Causes, Prevention, and Solutions

As a 3D printing enthusiast with over 20 years of experience, I can tell you that the nozzle is one of the most important, yet often overlooked components of a 3D printer. Being the last part in contact with the filament before extrusion, the nozzle plays a pivotal role in print quality and speed.

In this comprehensive guide from the warhammeruniverse.com team, I will cover everything you need to know about 3D printer nozzle wear and tear. We’ll explore the causes and signs of nozzle damage, materials and design choices, ways to prevent premature wear, when nozzles need replacing, and troubleshooting print quality issues related to worn nozzles. I’ll also share some of my best tips for extending nozzle life based on my two decades of 3D printing know-how.

By the end, you’ll have in-depth knowledge to select, use, and maintain nozzles for optimal print results. Be sure to check out our YouTube channel for accompanying video tutorials on changing and unclogging nozzles too!

Chapter 1: Understanding Nozzle Composition and Geometry

To understand nozzle wear, we first need to get familiar with the composition and geometry of nozzles. There are three main factors that influence performance and longevity:

- Nozzle Size

- Nozzle Material

- Nozzle Bore Diameter

Nozzle Size

The overall physical size and mass of the nozzle body impacts thermal conduction. Bigger nozzles can transfer heat faster and reach higher temperatures for faster extrusion speeds. Common sizes are:

- Standard: 12-13mm long – For most desktop printers

- Volcano: 21mm long – For 3x faster speeds

- Super Volcano: 50mm long – For ultra high-temp filaments

Nozzle Material

Nozzles are made from metals like brass, stainless steel, hardened steel, or plated copper. Each has pros and cons:

- Brass: Low cost but wears faster

- Stainless Steel: More durable than brass

- Hardened Steel: Extremely abrasion resistant

- Plated Copper: Excellent heat transfer, resists sticking

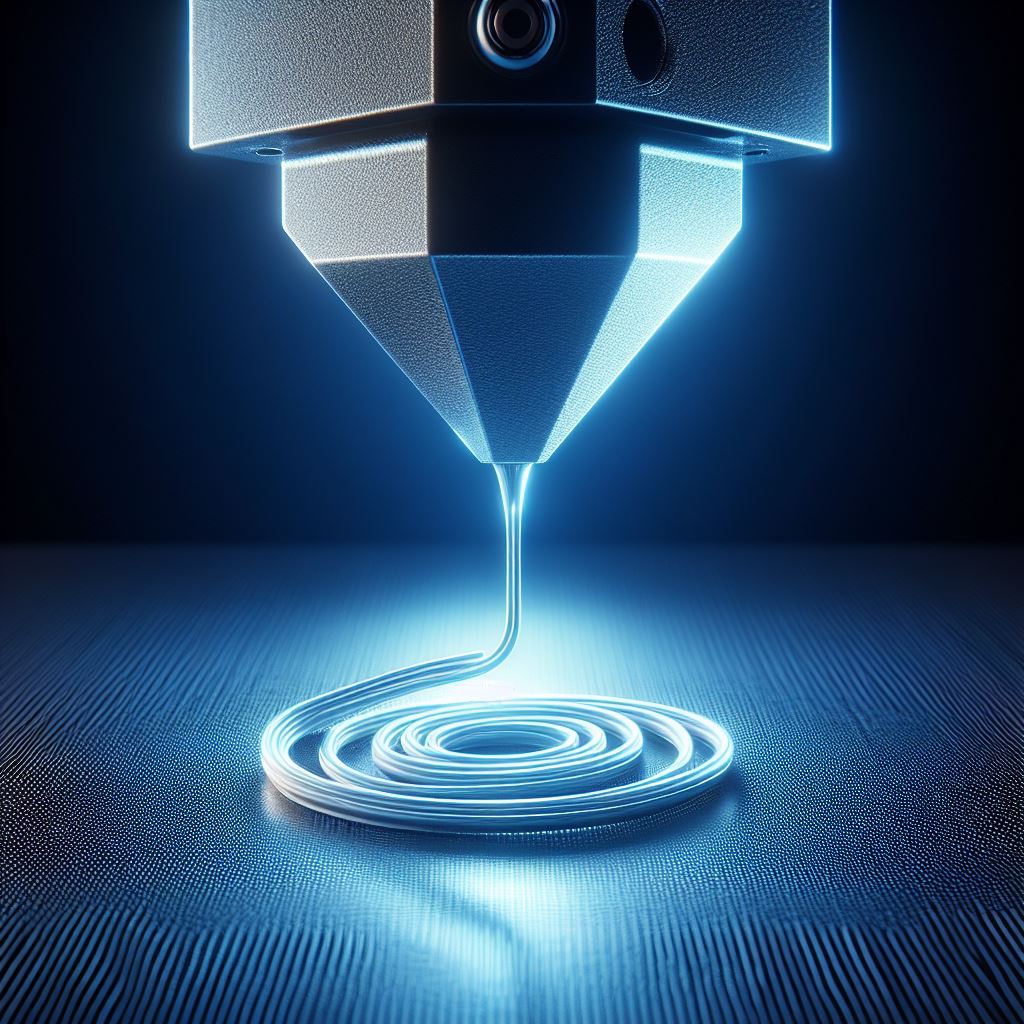

Nozzle Bore Diameter

The inner hole size ranges from 0.1 to 1.2mm. Wider openings extrude more material but reduce precision. 0.4mm is the standard for balancing speed and accuracy.

Now let’s move on to understanding the wear process and how to mitigate it!

Chapter 2: Causes of Nozzle Wear and Tear

These three main factors contribute to degrading nozzle condition over time:

Friction from Printing Abrasive Materials

Filaments reinforced with carbon fiber, metal particles, wood, or glow particles create internal abrasions. The rough edges slowly damage the inner bore.

Repeated Cold Pulls and Nozzle Clearing

Frequent cold pulls and aggressive clearing methods like torching or drilling physically scrape and erode the thin nozzle tips.

Exterior Damage from Crashes and Unclogs

The nozzle’s thin protruding tip is vulnerable to collisions with the print bed or debris. Any bending, dulling or marks reduce precision.

Chapter 3: Signs Your Nozzle Needs Replacing

Subtle nozzle wear can be tricky to diagnose. Watch for these printing symptoms and physical signs:

Print Quality Issues:

- Stringing

- Under-extrusion

- Poor layer adhesion

- Blobbing

Physical Nozzle Damage:

- Enlarged bore diameter

- Inner scratches or grooves

- Shortened or blunted nozzle tip

Take a close inspection if you notice declining print quality. Take preventative steps before catastrophic nozzle failure!

Chapter 4: Material Selection Guidelines

Follow these pairing guidelines to reduce abrasion based on your go-to printing filaments:

PLA, ABS, PETG, Nylon:

- Brass or stainless steel nozzles

- Avoid coated copper or ruby

Flexible Filaments (TPU, TPE):

- Plated copper resists sticking

Abrasives (Carbon Fiber, Woodfill):

- Hardened steel or ruby tipped nozzle

Now let’s get into specific methods for extending the working life of your nozzles!

Chapter 5: Preventing and Slowing 3D Printer Nozzle Wear

- Purchase Quality Nozzles

High manufacturing standards ensure dimensional accuracy and longevity. Stay away from the real cheap nozzles.

Some top recommended brands:

- Micro-Swiss (plated copper)

- E3D (hardened steel)

- Nozzle X (tungsten carbide)

- Matterhackers (high-grade stainless steel)

- Rotate Between Multiple Nozzles

Dedicate nozzles for abrasive vs non-abrasive use. Swap nozzles to spread wear across your inventory.

Have dedicated nozzles on hand in 0.4mm and 0.6mm sizes for flexibility depending on the print. Always have spare replacements ready to swap in when wear is observed.

- Clean and Handle Carefully

Gently wipe tips clean instead of scraping. Store safely to prevent falls and tip damage.

Use the nylon cleaning sticks and brass brushes designed specifically for clearing nozzles to avoid wearing down the inner surfaces.

- Print Slowly at Low Temperatures

Lower speeds and temperatures reduce internal friction and material sticking.

For standard PLA and ABS, print 5-10 degrees cooler and 10-20mm/s slower than max temps/speeds. But don’t impede flow too much.

- Upgrade to Wear-Resistant Metals

Treat your machine to some hardened steel, plated copper or ruby nozzles.

The E3D Hardened Steel Nozzle resists abrasive composites. And the Micro-Swiss plated copper increases heat transfer for sticky filaments like PETG. Well worth the extra investment!

Consistently following those basic guidelines will maximize the working life of your nozzles.

Chapter 6: Nozzle Replacement Best Practices

When nozzle replacement is inevitable either due to wear or to change sizes, follow this drill:

- Heat up the nozzle to printing temp to loosen any plastic residue.

- Use the provided tools to carefully unscrew counterclockwise without bending.

- Clean the threading in the heater block thoroughly before installing the new nozzle.

- Screw in the new nozzle until just snug – don’t over tighten!

- Do a cold pull, PID tune, extruder calibration, and bed leveling to dial in your printer with the refreshed nozzle.

Refer to our step-by-step video guide on changing nozzles for more details. Be extra cautious when replacing nozzles and avoid cross-threading!

Chapter 7: Salvaging Worn 3D Printer Nozzles

Before throwing damaged nozzles in the scrap pile, consider these ways to extend usefulness:

Recalibrate and Adjust Slicer

For minor inner diameter growth under 0.6mm, update nozzle size in slicer settings and the flow rate.

Precision Rebore Larger Sizes

Carefully bore out to create larger sized nozzles up to 2mm with proper drilling tools. Risks clogs.

Repurpose for Low-Quality Prints

Use degraded nozzles for quick draft prints rather than fine detail models to get more mileage.

Rebore with caution and understand the tradeoffs of using truly worn-out nozzles. In most cases, replacement is the wisest option for consistency.

Chapter 8: Concluding Thoughts on Nozzle Longevity

To wrap up, nozzle material selection, preventative maintenance, and handling practice awareness all play key roles in nozzle lifespans.

With non-abrasive filament, quality brass nozzles can last over 1000 print hours. But abrasives can rapidly degrade in under 100 hours.

Conclusion

Hopefully this all-encompassing reference guide from myself and the Warhammer Universe team has armed you with the knowledge to achieve longer 3D print nozzle usage without costly mid-print failures!

Let us know if you have any other nozzle care questions. And remember to tap into the trove of tutorials on our YouTube channel for visual demonstrations to master nozzle maintenance.

Related Articles

- Revolutionize Printing: Best 3D Tactics Guide

- Explore The best 3d printers for warhammer miniatures and for fine-tuning your strategies in our comprehensive guide to elevate your success on the battlefield. Uncover the art of mastering 3D printing for miniature perfection.

- Optimize Quality: Ultimate Temperature Calibration Tips

- Unlock the potential of your prints with our best guide on 3D printer temperature control. Achieve unparalleled print quality by mastering the art of temperature optimization.

- Troubleshoot Like a Pro: 3D Printer Bed Woes Solved

- Overcome challenges with our expert the best 3d guide on problem-solving Printer bed issues. Dive into troubleshooting tactics, ensuring your prints adhere flawlessly for a seamless crafting experience.

- Crafting Wonders: Beginner’s Guide to Custom Miniatures

- Immerse yourself in personalized miniatures with our guide to creating custom miniatures. Perfect for newcomers, unlock the secrets of sculpting and printing unique figurines.

- Painting Mastery: How to Prime and Paint Miniatures

- Polish your miniature painting skills with our beginner-friendly guide on how to prime and paint 3D printed miniatures. Discover techniques to breathe life into your creations.

- Preserve Your Army: Guide to 3D Printing Warhammer

- Dive into the world of Warhammer armies with our detailed guide on 3D printing Warhammer miniatures. From printing to painting, preserve your army with expert advice.

- Size Matters: Nozzle Size Importance Unveiled

- Explore the significance of nozzle size in 3D printing. Discover why nozzle size matters and how to make the perfect choice for your printing endeavors.

- Embark on Your Journey: Getting Started with 3D Printing

- Ready to start printing your own miniatures? Our guide on getting started with 3D printing is perfect for beginners. Unlock the secrets of creating your unique figurines.

- Pro Tips Unveiled: 3D Printing Warhammer Figures

- Enhance your 3D printing skills with our pro tips for 3D printing Warhammer figures. Elevate your craft with valuable insights and techniques.

- Discover and Print: Guide to Miniature Exploration

- Explore the world of Warhammer with our guide on how to find and print miniatures. Uncover the joy of discovering and printing your favorite models.