Speed vs Quality Test Prints for 3D Printers: Finding the Ideal Balance for Your Models

As a passionate 3D printing enthusiast with over 20 years of experience, I’m constantly experimenting to find the perfect balance of print speed and quality for my miniatures and terrain. Getting those dialed in can be the difference between a smooth print and a failed mess!

In this comprehensive guide, I’ll break down everything you need to know about how print speed impacts your models on a Prusa, Ender, or any FDM printer. You’ll learn the basics of speed settings, how speed affects accuracy and surface quality, tips for tuning, and ideal speeds for different filaments. Let’s geek out on slicer settings together!

What Exactly is “Print Speed” on a 3D Printer?

When I first got into this hobby, I was confused by all the vague talk about “fast” and “slow” printing. Print time depends on so many factors like model size, nozzle diameter, layer height etc. So what do we mean by print speed?

Print speed refers specifically to the rate at which your print head moves in the X and Y axes to deposit material, measured in mm/s. A faster speed means the print head traces each layer more quickly. This reduces overall print time but can also cause issues like ringing/ghosting, poor adhesion, and loss of detail.

Slower printing yields better accuracy but takes longer. Most slicing software lets you configure separate speeds for things like:

- Overall default print speed

- First layer(s) speed

- Infill speed inside the model

- Outer wall/perimeter speed

- Support structure speed

- Non-print travel speed between sections

Let’s look at how tweaking these parameters affects print quality…

Faster Print Speeds: Watch Out for These Flaws!

When I first started 3D printing, I immediately cranked the speed way up. I mean, who wants to wait around? While faster prints seem tempting, too much speed can seriously degrade quality and cause failed prints. Here are some telltale issues to watch out for:

Ghosting/Ringing

Ever see ripples or wavy bumps on your print’s flat surfaces? This “ghosting” happens when high speeds create vibrations, causing the print head to overshoot positions and layers not to align properly.

Slowing down is the #1 fix! Reducing acceleration and jerk settings also helps.

Poor Layer Adhesion

Too much speed causes airflow that can cool layers before they bond. Slow down, especially on the first layer, to let it fuse fully to the print bed.

Holes from Under-Extrusion

When print speed exceeds the filament flow rate, you get gaps and holes from under-extrusion. Normally the slicer will auto-calculate flow rate to match speed, but bugs happen.

Jams and Clogs

Soft filament like TPU is especially prone to binding up if forced through the nozzle too quickly.

Warping and Shrinkage

Fast printing can increase thermal expansion and contraction, causing the corners of tall narrow models to lift or the whole print to be undersized.

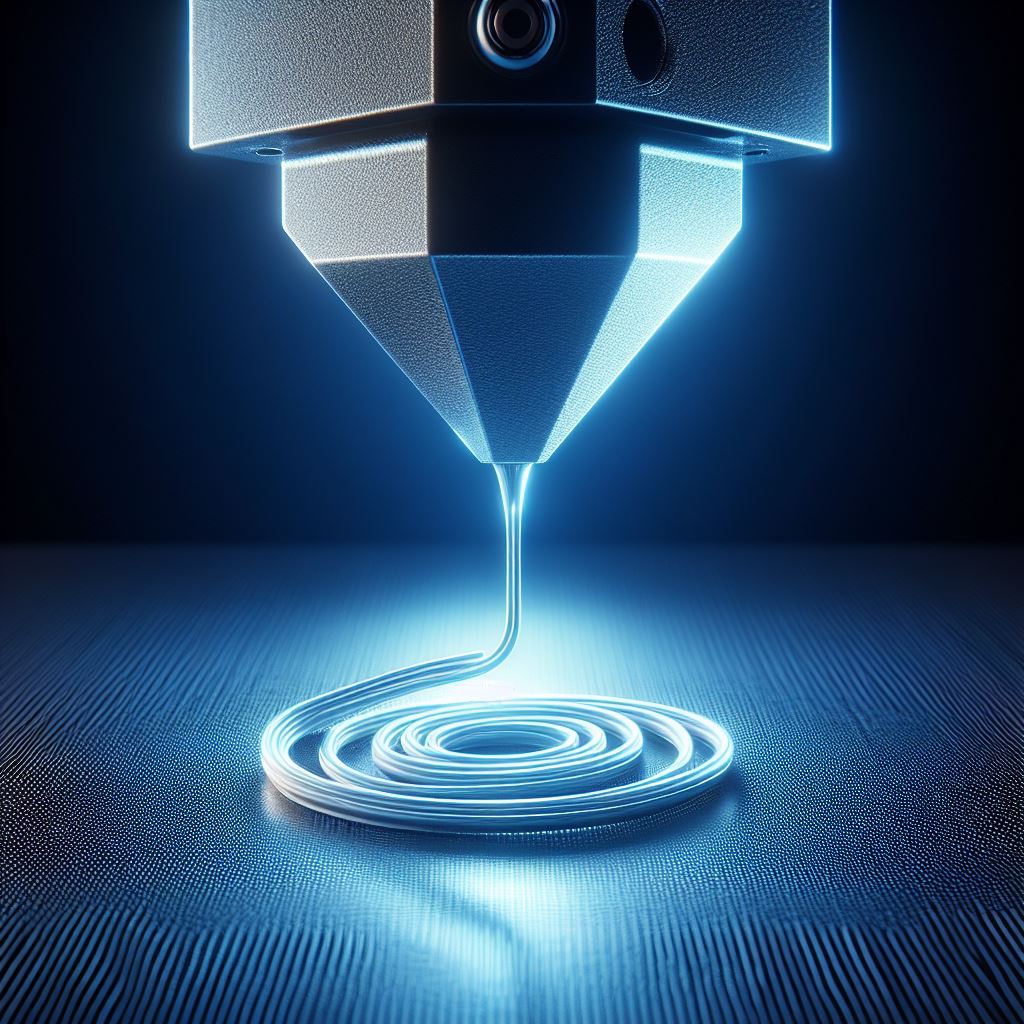

Slower Print Speed for Better Accuracy

While blazing speeds sound impressive for bragging rights, most users print PLA around 60mm/s max for good quality. Slowing down improves:

Surface Quality:

More time allows filament to fully melt and flow smoothly onto previous layers for a cleaner finish.

Dimensional Accuracy:

Warping and shrinkage are minimized when each layer cools gradually. This helps achieve the designed dimensions.

Fine Detail Precision:

With less vibration and inertia, the print head can follow intricate model geometry more exactly. Supports higher resolution slicing.

For the smoothest, most accurate terrain pieces to showcase your mini painting skills, slower is better!

Print Speed Tower Test Model

Rather than guessing the max usable speed for great quality, I recommend printing a speed tower to dial it in empirically!

Download an STL model file that is sliced to print identical shapes at incrementing speeds up to 200mm/sec. Visually inspect where quality degrades unacceptably.

I also suggest tuning acceleration/jerk and checking speeds for different filament materials…

Recommended Print Speeds Per Filament Type

Filament Type Typical Speed Max Speed Notes

PLA 60mm/s 150mm/s Fast flow rate capability enables very high speed. Warp-resistant.

ABS 60mm/s 60mm/s Similar quality to PLA, but prone to warp at extreme speeds

PETG 50mm/s 60mm/s Oozes easily so faster non-print travel speeds help

TPU/Flexible 20mm/s 20mm/s Very low maximum speed threshold before binding/jamming

Nylon 40mm/s 50mm/s Large parts benefit from annealing above glass transition temp

Of course you should also reference your specific printer’s specs, the filament manufacturer guidelines, and any recommendations from the Warhammer Universe YouTube channel for optimal configurations!

Further Refining Based on Print Section

Quality purists cringe at this next part, but I actually jack up speed for internal infill since nobody sees it anyway! Default print profiles also often have a slower first layer speed for better bed adhesion.

You can further tweak print speeds separately for:

- Infill (inside)

- Perimeters/walls (outside detail)

- Top and bottom skins

- Supports (disposable structure)

I actually print supports super fast despite the lower quality. They get removed anyway!

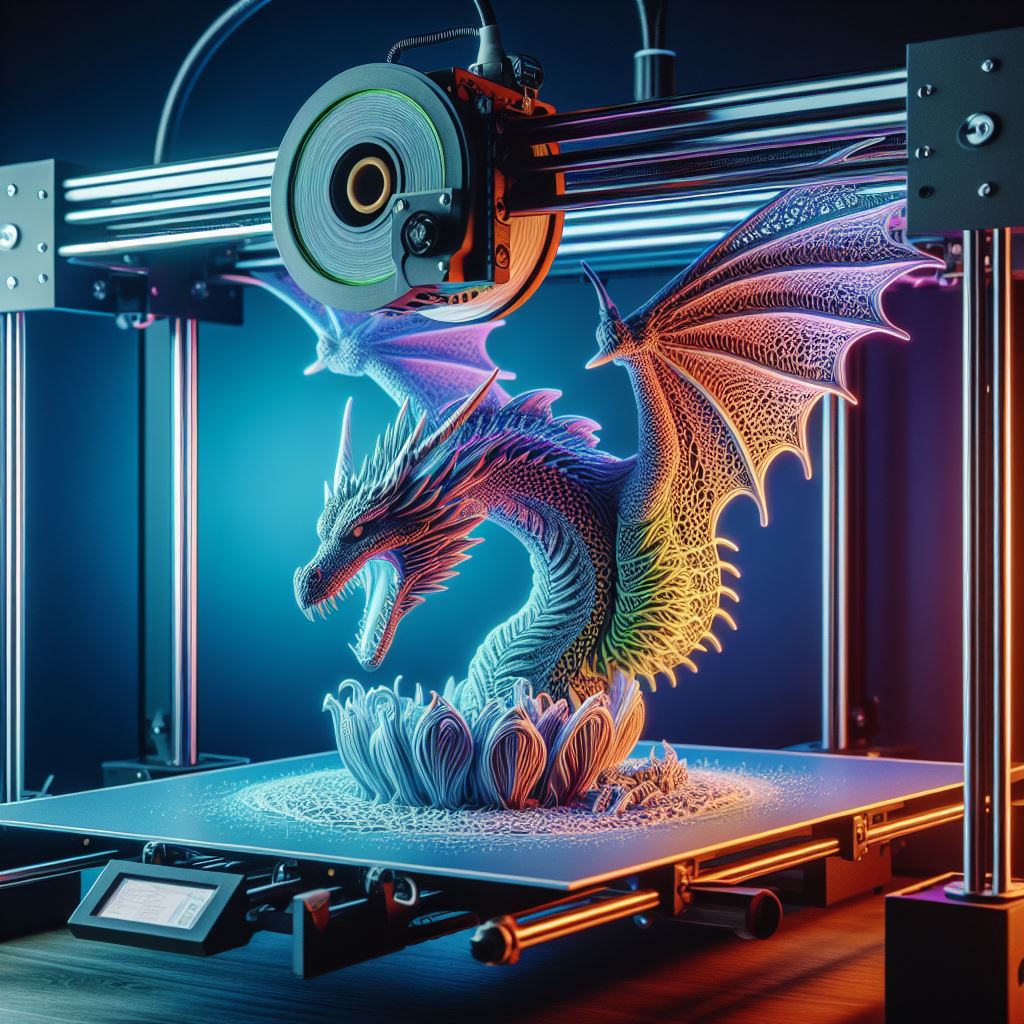

Balancing Speed vs Quality for Your Needs

At the end of the day, finding the best print speed is a balancing act between:

- Faster overall print time so you can iterate on mini/terrain designs faster and game more!

- Smoother surfaces, crisper details, accurate sizing to show off your elite painting skills

Experiment with speed towers and tweak slicer settings until you nail the right combo for your printers, filament, and applications! Soon you’ll be cranking out perfect miniatures and jaw-dropping terrain fast.

Fine Tuning Acceleration for Optimal Speed

When pushing print speeds faster, I also tweak settings like acceleration and jerk to help compensate.

Acceleration determines how quickly the print head ramps up to the target speed. Too much acceleration can cause missed steps and ringing.

Jerk controls the rate of change in acceleration between moves. Excessive jittering motion also contributes to ghosting issues at high velocities.

Dialing in the right acceleration and jerk settings for your printer can help achieve clean, ringing-free prints at faster print speeds. I suggest starting around 500mm/s^2 acceleration and 8-10mm/s jerk.

Preheating to Prevent Flexible Filament Jams

When printing soft flexible filaments like TPU, it’s crucial to heat up the nozzle chamber to at least 220C FIRST before inserting filament during printer startup.

Cold flexible plastic is stiff and can kink inside the Bowden tube causing frustrating clogs. Save yourself some headaches!

Post Processing Rough High Speed Prints

For draft prints focused on speed over quality, I often use filler primer, sanding, and sometimes an acetone bath on ABS prints. This helps smooth layer lines faster than optmizing slicer settings alone.

Using Support Blockers for Overhangs

Maximizing support structure speed leaves poor quality underside surfaces but…

Clever overhang modeling techniques like support blockers can enable fast prints completely sans supports on gently angled surfaces. This places small rest pads in mid air exactly where needed to brace those tricky areas during printing.

Troubleshooting Extruder Skipping Issues

Listen closely to your extruder gear during printing. You may hear frequent small slips or skips indicative of filament struggling to keep pace with an overly ambitious print speed.

Beyond tuning acceleration, consider lowering speed, raising hotend temp, adjusting gear tension, or upgrading to a geared Titan style extruder.

Let me know if you have any other questions in the comments or stop by our YouTube channel for more tips. Happy printing!

Related Articles

- Boost Printing Success: How to do the First Layer in 3d printing

- Uncover the secrets to achieving a flawless first layer in 3D printing. Our comprehensive guide ensures your prints start with precision and quality.

- 3D Printing Essentials: Nozzle Wear Prevention for 3d printers

- Delve into the causes, prevention, and solutions for nozzle wear in 3D printing. Elevate your printing experience with expert insights for lasting performance.

- Hobbyist’s Choice: Best 3D Printers for Warhammer

- Explore our guide to the best 3D printers tailored for miniature enthusiasts. Elevate your hobby with cutting-edge technology and reliable recommendations.

- Optimize Print Quality: 3D Printer Calibration Guide

- Elevate your printing game with our guide to 3D printer temperature calibration. Achieve the best print quality by mastering temperature settings.

- Troubleshooting Wisdom: Bed Adhesion Fixes for 3d printers

- Overcome bed adhesion challenges with our troubleshooting guide. Discover effective solutions to ensure your prints stick securely to the bed.

- Sculpt and Print: Custom Miniature Creation for Warhammer

- Unleash your creativity with our guide to sculpting and printing custom miniatures. Perfect for beginners, this guide brings your unique designs to life.

- Prime and Paint Like a Pro: Miniature Painting Guide

- Elevate your miniature painting skills with our beginner’s guide. Learn the art of priming and painting 3D-printed miniatures with professional tips.

- Preserve Your Army: 3D Printing Warhammer Minis

- Dive into the world of 3D printing Warhammer miniatures. Our guide covers printing, painting, and preserving your army for epic battles.

- Size Matters: Nozzle Size Guide

- Understand the impact of nozzle size in 3D printing and how to choose the right one. Size matters—optimize your prints for precision and speed.

- Embark on 3D Printing: Getting Started Guide

- Ready to print your own miniatures? Our guide for beginners covers everything you need to get started on your 3D printing journey.