Filament Mixing Color for 3D Prints: Guide

Fellow hobbyists, welcome! As a miniature painting enthusiast with over 20 years experience, I could not be more delighted to provide this extensive filament color mixing resource. If plain single color prints have you down, read on as we unlock a universe of possibilities!

In this guide we’ll cover:

Filament Mixing Methods Overview

There are 5 major approaches to injecting color variety into your prints:

1. Manual Color Swapping

Pausing a print mid-way and swapping filament colors allows switching colors at distinct layers.

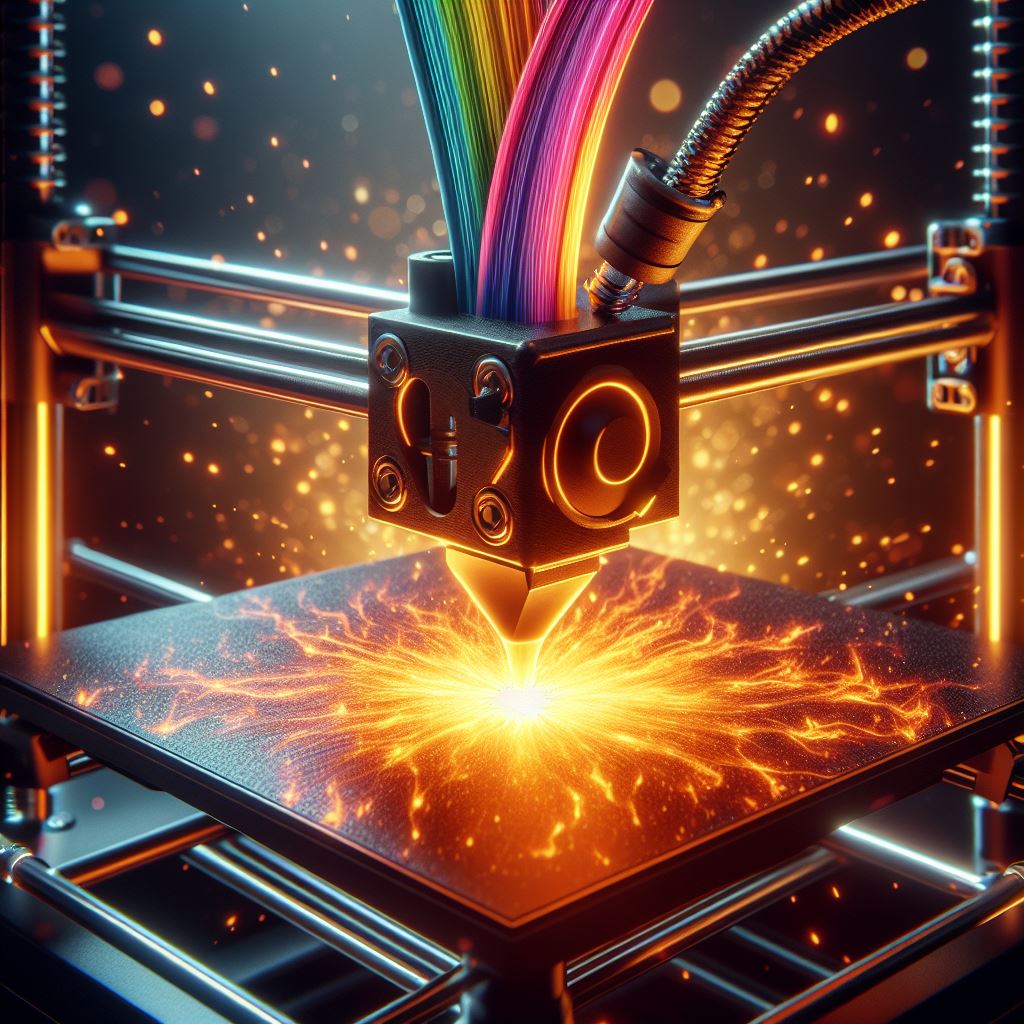

2. Dual Extruder Printers

Specialized machines with two independent nozzles allow mixing filaments.

3. Multi-Material Combiners

Devices like the Palette continuously combine filaments for intricate multi-material prints.

4. Pre-Colored Filament

Vibrant filaments like rainbow, color shifting, and custom dyed remove the need to paint after.

5. Post-Print Painting & Finishing

Adding acrylic, airbrush, or hydrographic coatings allows total creative freedom.

In-Depth Explanations of Mixing Approaches with Pros & Cons

Let’s explore the key benefits and limitations around each method:

Manual Color Changing Mid-Print

One of the simplest ways to integrate multiple colors is to manually pause your print at certain layers and swap filament.

For example, you may print the torso of a mini figure in blue, then pause the print once finished, swap to brown filament, and resume printing the legs.

To leverage this technique:

Insert pause commands at target layers in your slicer software

When the print reaches the pause, swap filament

Resume print once new filament is loaded

This allows distinct color regions aligned to components.

Pros:

Extremely simple to try

Leverages existing print setup

Cons:

Limited to one color per layer

Remembering/executing many pauses can be cumbersome

Overall, manual color changing is a great budget way to experiment with multiple colors.

Specialized Dual Extrusion Machines

Purpose built printers with dual extruders and nozzles unlock mixing filaments within prints automatically. As one nozzle lays down material, the other parks to the side. They can toggle precisely.

For example, as the print head moves over the base, nozzles can alternate depositing brown and green filament to blend a grassy terrain texture.

This avoids pauses and lets two colors occur at any region, even sharing the same layers.

Pros:

True filament mixing automation

Multi colors simultaneously

Cons:

Dual extruder machines are expensive

More complex to operate

If pursuing advanced techniques, devices like the FlashForge Creator Pro 2 provide excellent results.

Multi-Material Splicing Devices

While most printers have a single nozzle, attachments like the ingenious Palette continuous filament combiner allow extruding complexes mixes from multiple materials or colors.

These machines seamlessly cut and splice up to 8 filament feeds, joining them into one continuously integrated output strand fed to your printer based on model requirements.

For example, they can perfectly integrate flexible segments as needed for cushioning into a rigid plastic print by inserting the specialty filament only at certain sections. This opens huge possibilities.

Pros:

Unlock intricate multi-material prints

Automate complex color mixing

Cons:

Adds cost for additional hardware

Needs integration with printer

If exploring advanced filament blending, the Palette system provides professional yet accessible results.

Pre-Colored & Specialty Filaments

Beyond conventional plastic filament, a vibrant world of color varieties exists:

Rainbow Filament: Randomly mixes colors throughout a spool for fun prints

Color Shift Filament: Changes hues based on temperature

Co-extruded Filaments: Interleaves two distinct colors without mixing

Dyed Nylon Filaments: Customizable tie-dye like effect when produced

Prints exhibit the colors, blends, and textures directly without painting.

Pros:

Create vivid prints easily

Allows some great effects

Cons:

Limited color control

Specialty filament opens unique possibilities!

Post-Print Painting & Hydrographic Dipping

For full creative freedom (especially with SLA prints), decorate 3D printed pieces with coatings:

Acrylic Paints: Affordable way to hand paint details

Airbrushing: Enables smooth color gradients

Hydrographic Film Transfer: Waterslide decal-like coloration

Pros:

Endless customization options

Can create incredibly vibrant pieces through layering

Cons:

Very time and labor intensive

If pursuing completely custom coloring, paints and hydrographic delivery stunning results.

Filament Color Mixing Process Comparison: FDM vs. SLA

We’ve covered a variety of color integrating options – but how do they complement key 3D printing processes like FDM and SLA?

Evaluating the comparative strengths and weaknesses around resolution, surface finish, throughput, and post processing reveals ideal applications.

Here is an overview comparison:

As shown, SLA’s ultra smooth surface finish lends beautifully to painting but limits integrated color mixing compared to FDM’s simpler nozzle extrusion.

Considering use cases and required results helps select optimal combinations of printers, mixing methods, and post processing choices.

Killer Applications to Inspire Your Color Prints

The expanded world of color 3D printing unlocks new possibilities across:

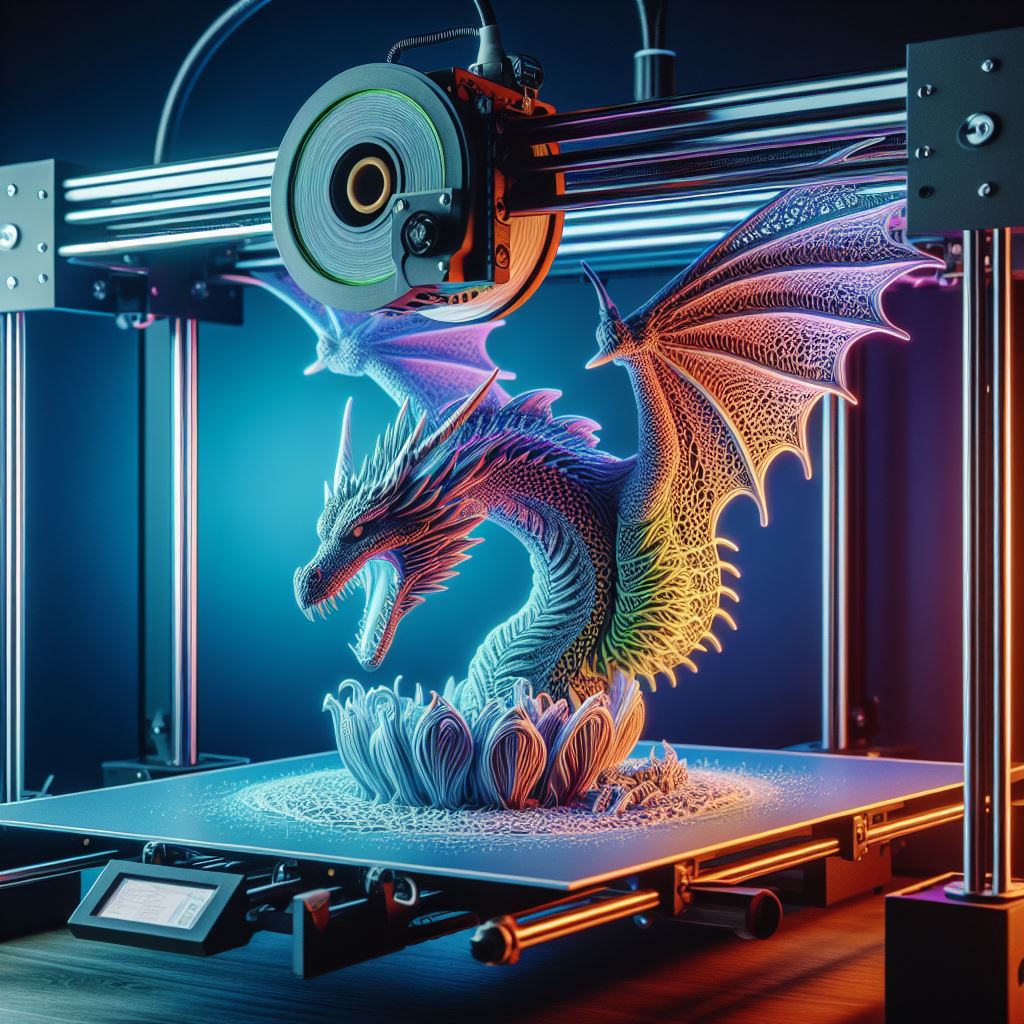

1. Tabletop Gaming Miniatures & Terrain

From tiny goblins to towering castle walls, vibrant colors take your game pieces to new levels. Both FMD and SLA printing help hobbyists customize pieces.

2. Color Concept Prototypes

Product designers leverage color prints early on to assess consumer response to proposed colorways and materials. Shapeways and Sculpteo even offer full color 3D printing services for visualization.

3. Dazzling Decor Pieces

Blend beautiful filament mixes or hand paint decorative art pieces, vases, custom figures, awards, and more.

4. Custom Collectible Figurines

Produce the vivid superheroes, lovable pets, favorite game characters and other collectibles you’ve always dreamed of with compelling color schemes. Services like HeroForge even allow choosing colors digitally.

The possibilities are truly endless – what unique ideas do you have? Please share your visions in the comments or on our Youtube channel!

Expert Printing Tips for Stunning Results

While we’ve covered a variety of techniques, dialing in these key best practices helps ensure exceptional printed outcomes:

1. Optimal Extrusion Temperatures

Tune nozzle heat settings for smooth flow – too cold and filament won’t melt fully, too hot risks clogs. Target manufacturer guidance.

2. Bed Leveling Essentials

Proper thermal bed leveling ensures first layer adhesion – critical for blending colors well.

3. Nozzle & Print Speed Calibration

Balance quality against print duration by calibrating speed. Slow precison for details!

4. Software Slice Settings

Dial in layer height, infill, supports, cooling and more in your slicer software.

5. Material & Machine Specific Guidance

Follow special considerations around optimal environments, storage, machine maintenance etc. to avoid surprises!

And those are just the basics! For step-by-step guidance on calibration, adding dual extruders, and more be sure to check the in-depth tutorials over on our Youtube channel.

FAQs

Finally, let’s answer some common questions around advanced color mixing methods:

Q: What provides the strongest filament strength when mixing materials?

A: Look for extruders that integrate well thermally – large differences in melting temp or cooling cause issues.

Q: How should I finish special mixed prints?

A: Generally focus on protective clear coats rather than abrasives processes to preserve integrity.

Q: Why am I experiencing clogs or unexpected color changes?

A: Could be heat creep or tension problems – check for obstructions and reflow key parts like the heat break.

Q: What printers support advanced mixing tools like the Palette?

A: Most common machines have adapters available from Palette directly or via sites like Thingiverse – check compatibility lists.

Have a question not covered? Reach out in comments!

So whether you are looking to add bold color variety, intricate multi-material mixes, customized colorations, or some added “pop” through painting – unlocking the color potential of your printer is an exciting endeavor!

This comprehensive guide aimed provide the details you need to achieve gorgeous prints. Let us know if you have any other topics we should cover to further build expertise. And as always, happy printing!

Related articles

- Unleash Victory with Our Expert Tactics! Dive into our comprehensive guide on the best 3D printers for miniatures to discover top-notch strategies, ensuring triumph on the battlefield. Arm yourself with knowledge for unparalleled success.

- Mastering the Art: 3D Printing Tactics Unveiled! Explore the realm of successful 3D printing with our guide. Discover the best balance for your 3d print models and unlock the secrets to impeccable model creation. Elevate your craft with our expert insights.

- Revolutionize Your Print Quality – A Tactical Approach! Elevate your 3D printing game by exploring the guide for post-processing 3D prints. Our guide unveils revolutionary strategies to enhance your printing quality and achieve impeccable results on the battlefield.

- Dominating the Battlefield: A Miniature Printing Mastery! Conquer the art of miniature printing with our expert tactics. Learn why our guide on 3D printer temperature calibration is your key to dominating the battlefield. Arm yourself with knowledge for unparalleled success.

- Crafting Excellence: A Guide to 3D Printer Calibration! Achieve perfection in your prints with our guide on 3D printer temperature calibration. Explore the nuances of calibration for the best print quality for 3d printing miniatures, ensuring your models stand out with excellence.

- Sculpting Victory: 3D Printing Warhammer Figures Unveiled! Delve into the world of 3D printing Warhammer figures with our beginner-friendly guide. Uncover essential tips for success in our comprehensive guide on tips for 3D printing Warhammer figures. Arm yourself with knowledge for miniature mastery.

- Cost-Efficiency Unveiled: 3D Printing Miniatures on a Budget! Navigate the cost landscape of 3D printing Warhammer miniatures with our insightful guide. Discover budget-friendly solutions and cost-saving strategies in our comprehensive guide on cost of 3D printing Warhammer miniatures.

- Troubleshooting Triumphs: A Guide to Common 3D Printing Woes! Tackle common 3D printing problems head-on with our expert guide. Explore solutions and preventive measures in our comprehensive guide on fixing common 3D printing problems. Ensure your prints stand tall and error-free.

- Optimizing Precision: The Slicer Software Essentials! Unlock the potential of slicer software with our beginner’s guide. Navigate the intricacies of how to get models in slicer software for optimal prints. Elevate your printing game with our comprehensive guide.

- Stability in Structures: Conquering 3D Printing Challenges! Conquer the challenges of overhangs and bridges in 3D printing with our expert guide. Discover stability secrets for robust structures in our comprehensive guide on fixing overhangs and bridges in 3D. Arm yourself with knowledge for printing success.