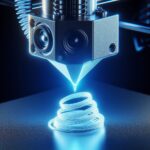

Guide for Improving 3D Print Quality: 20 Tips for Better Prints

Introduction: As an avid 3D printing enthusiast with over 20 years of experience creating miniatures, terrain, and custom models, I’ve learned that achieving a perfect 3D print takes patience, precision, and following best practices. In this comprehensive guide directly from our team at WarhammerUniverse.com, I’ll be sharing my top 20 professional tips for dramatically improving your print quality, no matter your skill level or type of printer.

I. Getting Started: Printer Setup and Calibration Proper initial setup and calibration ensure a strong foundation for success before you even slice your first model. Take the time to dial these in upfront and you’ll immediately notice improvements.

- Level the Bed Precisely: Leveling your heated print bed accurately is absolutely fundamental. Manually level with a sheet of paper before each print, slowly adjusting the knobs until you feel just a slight friction. Auto bed leveling sensors can help too. This guarantees proper first layer squish and adhesion across the whole surface.

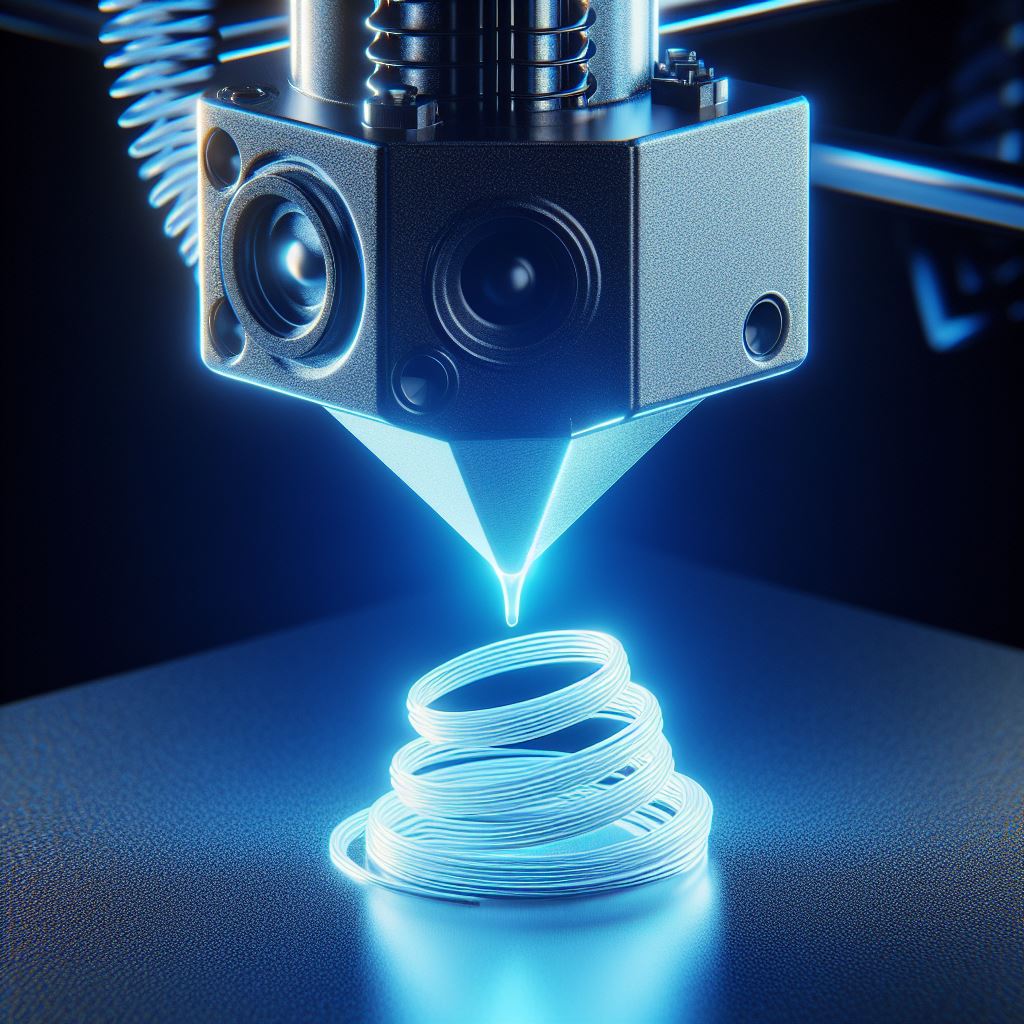

- Set the Right Nozzle Height: Closely related to bed leveling is setting the precise nozzle height above the surface, known as the “z-offset.” Too high and prints detach easily. Too low causes gouging or clogs. Refer to your printer manual and use test prints to hone this in over time. Getting this perfect eliminates many headaches down the road!

- Test Different Temperatures: Temperature directly impacts extrusion quality and surface finish. Try a range of nozzle and bed temperatures to understand how your specific filament behaves. Keep notes! Too hot, and you risk oozing, elephants foot, or layer shifts. Too cold causes poor adhesion and brittle layers. There’s a sweet spot for every material.

- Calibrate the Extruder Steps: Calibrating your extruder steps, essentially how much filament gets pushed per motor tick, ensures you’re extruding just the right amount. Follow an online guide to properly set this value. It prevents uneven extrusion and dimensional accuracy issues in your prints.

II. Upgrade Build Plate and Filament for Better Results Choosing the right bed surface and filament makes a huge impact. These upgrades are inexpensive ways to level up print quality substantially.

- Upgrade the Print Surface: The texture and adhesion properties of your heated print surface significantly influence bottom finish and how models stick. Try glass, PEI sheets, painters tape, gluestick, hairspray, or other options to optimize for your specific filament.

- Buy Quality Filament: Quality filament from reputable vendors results in significantly fewer print defects. Inexpensive no-name brands tend to have more inconsistencies leading to clogs, under-extrusion, and weak layers down the line. Proper storage using vacuum containers and desiccant prevents moisture absorption which ruins prints.

- Learn Slicer Software In-Depth: Understanding all your slicer’s settings gives you professional-grade control over the physics of the print process. While defaults work okay, custom supports, speeds, extrusion widths, retractions, and much more let you achieve truly incredible quality for your specific model and use case. Master your slicer, master your prints.

III. Printer Maintenance Tips for Better Reliability

Like any complex machine, routine preventative maintenance ensures your printer runs optimally long-term. Don’t neglect caring for your precision equipment!

- Keep Components Clean: Before each print session, clean debris off the hotend, print bed, rails, leadscrews, and belts using small brushes and cotton swabs soaked in isopropyl alcohol. Dust causes abrasion and clogs over time. A clean machine is a happy machine!

- Check Components and Calibrate Often: Periodically check belt tensions, rail lubrication, gantry leveling, screw preload, and other critical mechanical adjustments per your manual. Recalibrate z-offset and esteps too. This takes just minutes but prevents loose components or misaligned frames causing inaccurate prints down the road.

- Replace Nozzle When Needed: Brass printer nozzles slowly erode with extended use, developing ever-wider tips losing fine detail resolution. Swap for a fresh nozzle after lots of abrasive material prints or when you notice overhang quality declining. Choose the right size for optimal layer heights.

IV. Other Key Printing Tips for Perfect Layers

Dialing in slicing settings makes a major impact as well. Take your prints to the next level with these additional pro techniques:

- Print Supports When Needed: Enable supports in your slicer for steep overhangs and bridges to prevent sagging or failed layers. Try tree supports for easier removal. Getting support settings like density and Z-gap perfected demands some trial and error though.

- Slow Down Print Speeds: Sometimes faster isn’t better. Excess speed causes vibration ringing, layer shifts, and ugly surface texture. For maximum quality, 40-60mm/s is ideal. Acceleration and jerk control settings help too. Precision takes patience.

- Use Optimal Infill Settings: Infill creates internal lattice structures saving filament and print time. The right pattern at the right density keeps dimensional accuracy while ensuring solid external perimeter shells. Curved infill like gyroid yields incredibly strong prints.

- Enable Part Cooling: Carefully cooled layers mean cleaner details, tighter tolerances, and less warping as hot extruded plastic rapidly solidifies. Dual 5015 blowers are very effective. Warp-free ABS demands an enclosure with precise air control. Cooling makes a giant impact on overhangs!

- Adjust Filament Retraction: Retracting filament precisely between external layers and infill prevents “stringing” – those annoying wispy threads marring surface finish. Tuning retraction distance and minimum travel settings dials this in for clean, professional-grade prints.

- Post-Process for Perfect Finishes: Sanding, painting, annealing, smoothing, and other secondary post-print processing techniques give your prints truly amazing professional and artistic surface finishes. For example, vapor bathing ABS parts in acetone yields a beautifully glossy surface. Get creative!

- Tune Linear Advance: Linear advance (or pressure advance) is a setting that reduces blobbing and oozing during direction changes through dynamic tension control. This significantly improves print surface quality, especially on round edges. Calibrate correctly for your machine.

- Enable Z-Hop When Traveling: Z-hop instructs the print head to lift slightly when moving across open spaces to avoid collisions with already printed components, preventing nasty layer shifts or gouges. This saves many failed prints!

- Optimize Part Orientation: How you orient parts on the build plate dramatically influences print success, resolution, and aesthetics. Consider overhang angles, resolutions, visible facings, build time, filament use, and more when positioning parts with placement supports if needed. Rotating full models or just certain features can work miracles.

- Learn From Every Print: Approach every print as a lesson to incrementally improve quality over time. Examine flaws and imperfections closely, tweak related settings, and test again. Keep detailed notes regarding temperature, speeds, cooling, supports, and other parameters. Refer back to these for dialing in “recipes” for consistent, reliable success.

V. Closing Thoughts

With the right precision setup and following fundamental best practices that enhance print accuracy and surface finishes, you’ll achieve incredible prints that look factory made. Patience and persistence while learning your printer’s intricacies pay back exponentially with stunning models.

Don’t hesitate to experiment with temperatures, speeds, filaments, slicer tweaks, and various post-processing tricks to take your prints to the next level. And be sure to check our YouTube channel from WarhammerUniverse.com for step-by-step tutorial videos demonstrating techniques covered here. Happy printing!

Related Articles

- Unveiling Top Tactics – Explore our best 3d printers for miniatures and strategies for dominating the battlefield in this comprehensive guide. Elevate your success with expert insights on mastering tactical warfare and outsmarting opponents.

- Optimize Your Victory Path – Delve into the guide revealing the best model slicer for 3d printers tactics to sculpt your path to victory. Learn how to navigate models in slicer software for an optimized, strategic journey.

- Mastering the Battlefield Arts – Uncover the artistry of war with our guide on 3D printing Warhammer figures. Learn the best techniques for crafting stunning, detailed miniatures that stand out on the battlefield.

- Warhammer Warfare Decoded – Navigate the complexities of Warhammer warfare with our guide for fixing overhangs on 3d prints. Discover the best solutions for overcoming 3D printing challenges and building stable, resilient structures.

- The Art of Miniature Crafting – Unleash your creativity with our guide on 3D sculpting and printing. Learn how to turn your unique ideas into reality, sculpting and printing custom miniatures like a true artisan.

- Precision Printing Techniques – Elevate your 3D printing game with our guide to printer temperature calibration for 3d printers. Uncover the best practices for achieving impeccable print quality through precise temperature control.

- Cost-Effective Miniature Printing – Discover the economics of 3D printing Warhammer armies in our cost guide for warhammer 3d printing. Learn how to optimize expenses while still achieving top-tier miniature quality for your collection.

- Nozzle Mastery for Printers – Dive into the world of nozzle wear and tear prevention with our guide on nozzle wear and tear. Master the best techniques to extend the life of your printer’s nozzle.

- Troubleshooting Bed Adhesion – Resolve 3D printing challenges with our guide on bed adhesion problems. Explore best practices for ensuring your prints adhere securely to the bed throughout the printing process.

- Legal Insights for 3D Printing – Stay informed on the legal landscape with our guide on the legality of 3D printing Warhammer. Gain a comprehensive understanding of the legalities surrounding 3D printing in the Warhammer universe in 2024.